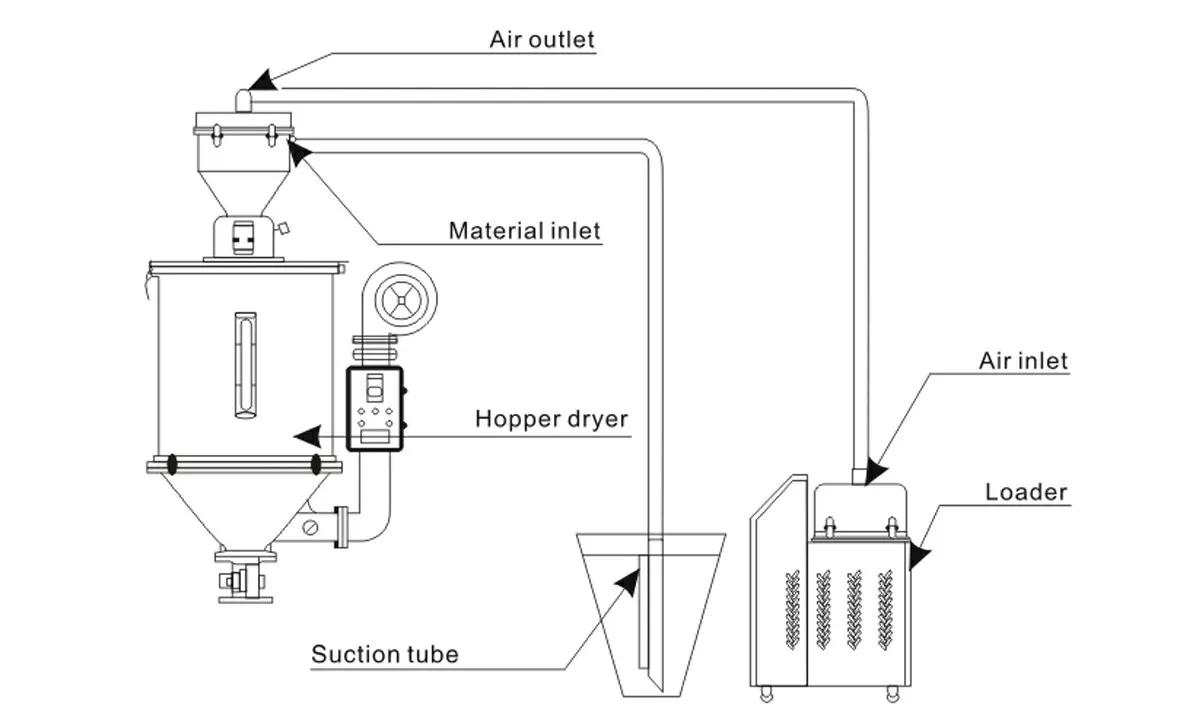

The Standard Separate Vacuum Hopper Loader is a high-efficiency material conveying system designed for industrial plastic processing.

It operates as a separate unit with vacuum suction, enabling flexible placement and easy integration with injection molding, blow molding, and extrusion machines. This reduces manual feeding, increases production efficiency, and ensures consistent material flow.

Key Benefits:

• Fully automatic material transfer

• Separate vacuum unit for flexible installation

• Compact and industrial-grade design

• Durable stainless steel hopper and components

• Low noise and energy-efficient operation

• Easy maintenance and filter cleaning system

Applications:

• Injection molding machines

• Blow molding machines

• Plastic recycling plants

• Extrusion production lines

Electrical Specifications:

• Power Supply: Single Phase / Three Phase (Model Dependent)

• Voltage: 220V / 380V – 415V

• Frequency: 50Hz

• Motor Power: 0.75kW – 3kW

• Control System: Automatic Timer / Sensor Controlled

• Overload Protection: Yes

• Safety Protection: Emergency Stop & Fuse Protection

-

Fully automatic vacuum material transfer

-

Separate unit design for flexible setup

-

Energy-efficient suction motor

-

Stainless steel hopper for durability

-

Compact industrial-grade construction

-

Low noise and vibration operation

-

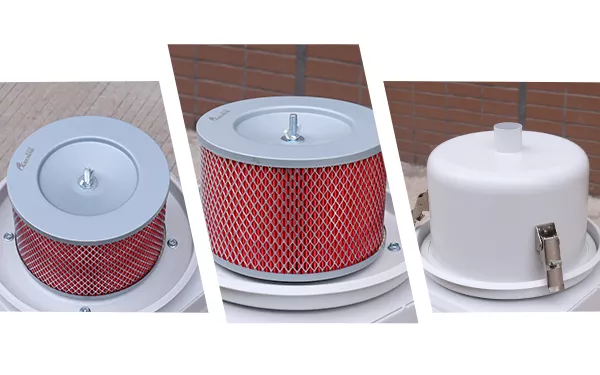

Easy maintenance with filter cleaning system

-

Compatible with injection, blow molding, and extrusion machines