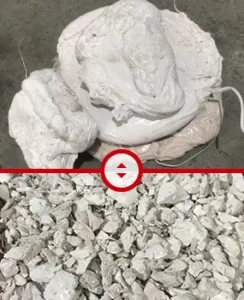

Our Heavy-Duty Plastic Granulator Machine is designed for efficient plastic recycling and size reduction. It is suitable for crushing plastic waste such as PET bottles, HDPE containers, injection molding rejects, blow molding waste, and industrial plastic scrap.

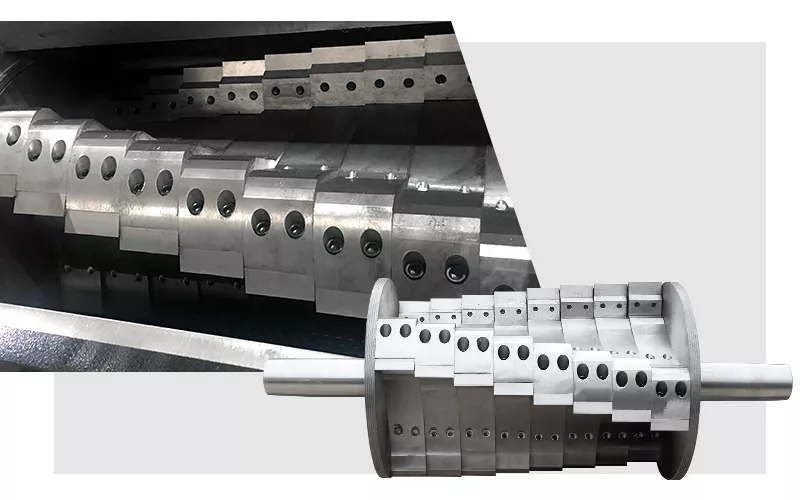

This machine is built with high-quality hardened steel blades and a powerful motor system to ensure long-term performance and durability.

Applications:

• Injection molding factories

• Blow molding plants

• Plastic recycling centers

• Industrial production lines

Available in different capacities:

- 5HP – 50HP models.

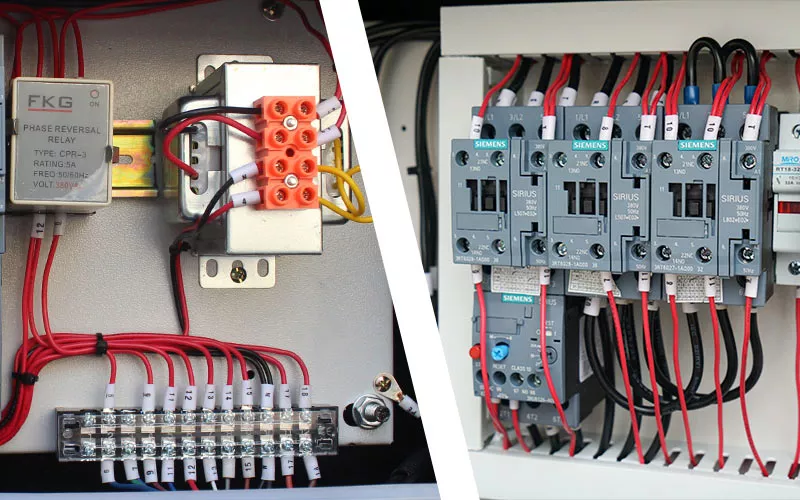

Electrical Specifications:

• Power Supply: 3 Phase

• Voltage: 380V – 415V

• Frequency: 50Hz

• Motor Power: 5HP – 50HP (depending on model)

• Control Panel: Industrial Electrical Control Panel

• Starter Type: Star-Delta / Direct Online (Model Based)

• Overload Protection: Yes

• Emergency Stop: Yes

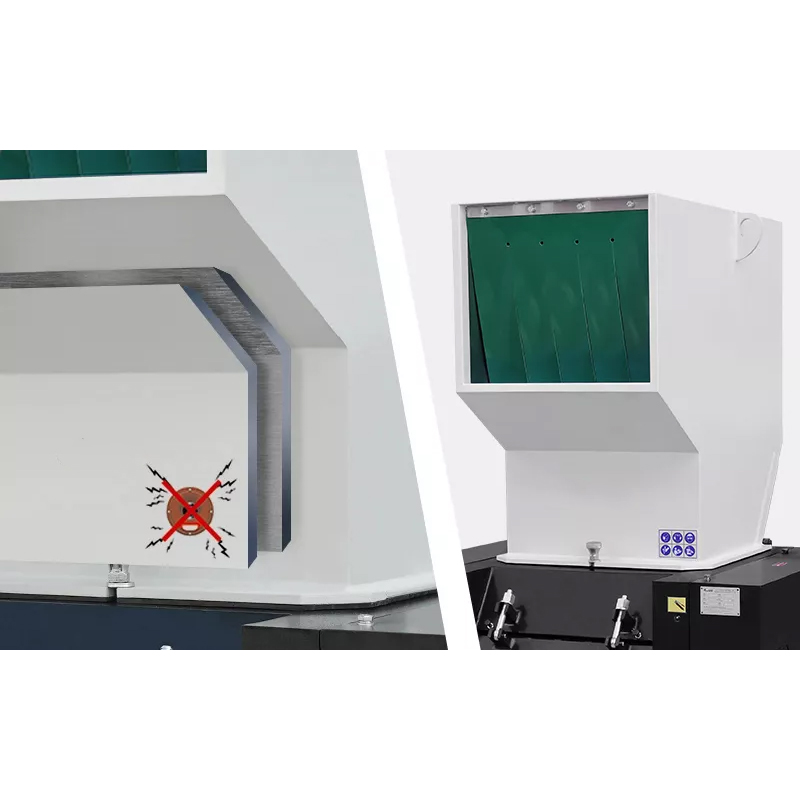

• Earthing Required: Mandatory

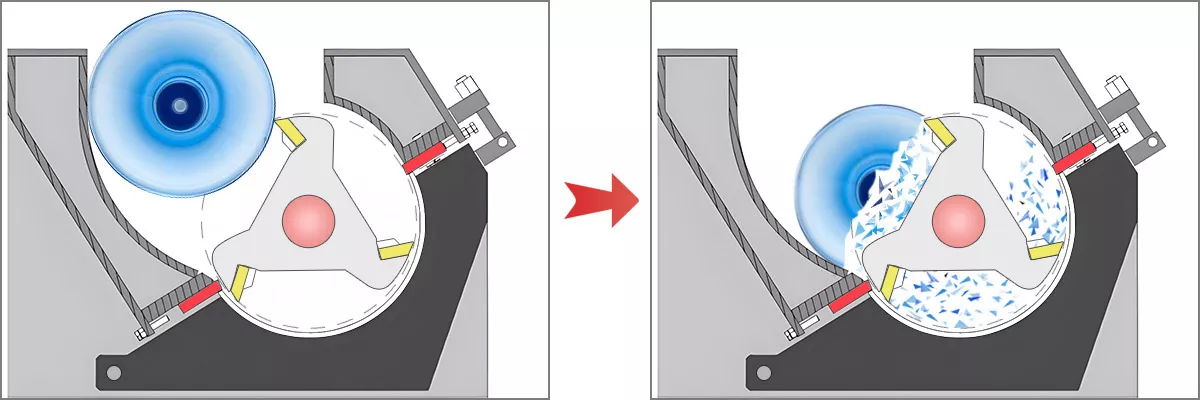

The crushing system ensures uniform and efficient size reduction of plastic waste using high-speed rotating hardened steel blades. It produces consistent granule size with minimal dust and low noise operation, improving recycling efficiency and production performance.

Granulating & Supportive Machines

Our granulating and supportive machines are designed to enhance plastic recycling operations with smooth material flow, efficient cutting, and continuous processing. Built for durability and high productivity in industrial environments.

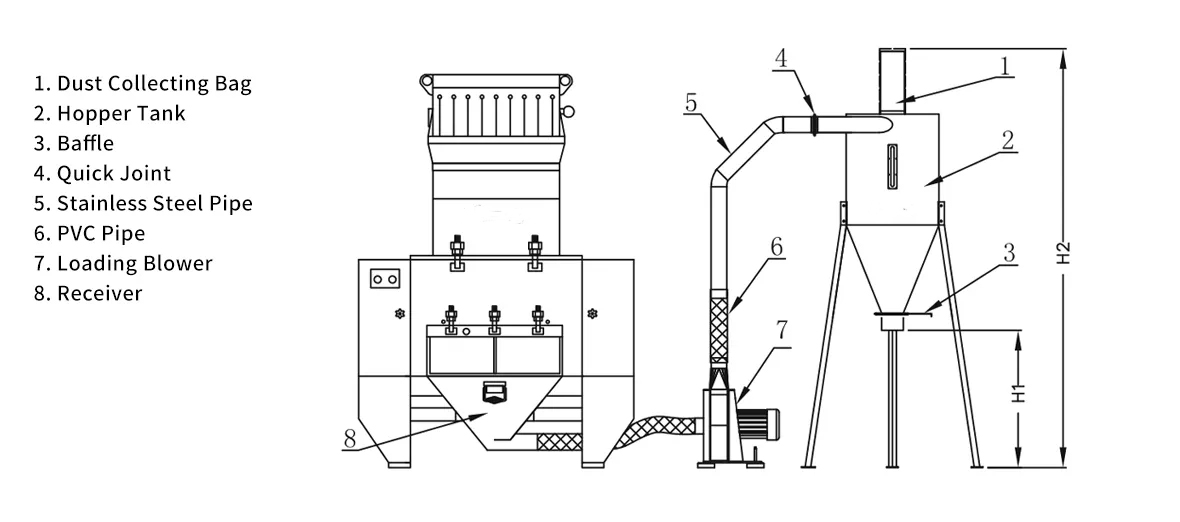

- Auto Collecting Unit

-

- The automatic collecting unit efficiently gathers crushed plastic material and transfers it directly to storage bags or containers, reducing manual handling and improving workflow efficiency.

-

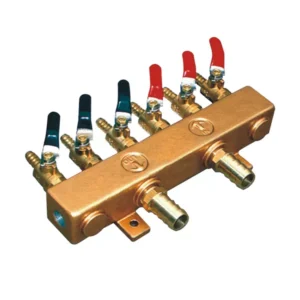

- Auto Power Shifting Device

-

- The auto power shifting device automatically adjusts power load according to material input, protecting the motor from overload and ensuring stable, energy-efficient operation.

-