Fiber Laser Cutting is a high-precision, efficient cutting process that uses a fiber-optic-based laser to cut or engrave a wide range of materials. Fiber laser technology is part of the broader category of laser cutting and stands out for its energy efficiency, precision, and suitability for cutting metals and non-metals.

How It Works:

- Laser Generation: The laser beam is generated using a seed laser, amplified through optical fibers, and delivered via a fiber-optic cable.

- Focusing: The laser beam is focused on the material’s surface using lenses or a cutting head, producing a high-energy density.

- Material Removal: The focused laser melts, burns, or vaporizes the material. A jet of gas (usually nitrogen, oxygen, or air) assists in clearing the molten material and improving the cutting process.

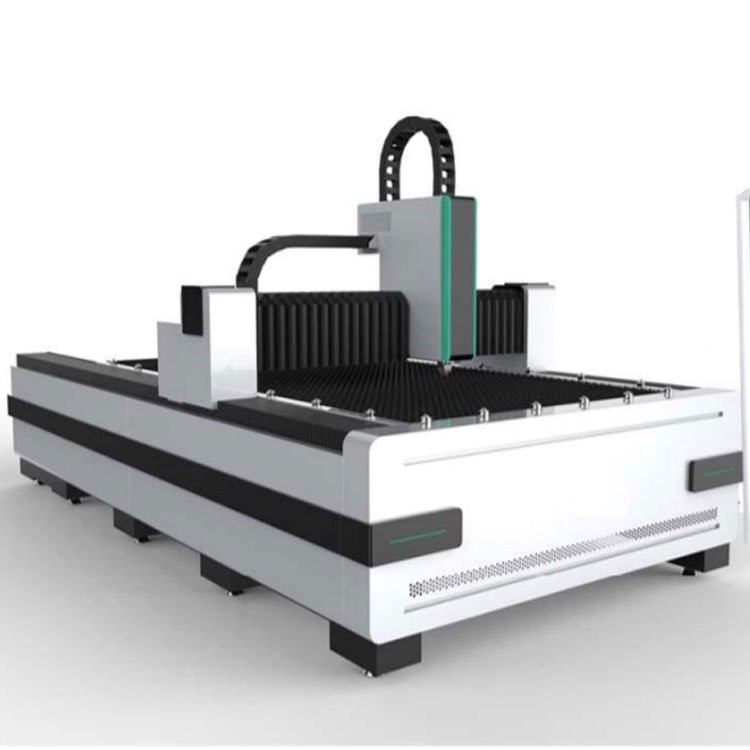

Key Components:

- Fiber Laser Source: Generates the laser beam with high power and energy efficiency.

- Cutting Head: Focuses the laser beam on the material.

- Optical Fiber: Delivers the laser from the source to the cutting head.

- Gas Supply System: Provides assist gases (oxygen, nitrogen, or compressed air) to enhance cutting.

- Worktable: Supports the material being cut.

- CNC Controller: Automates and controls the cutting process for precision.

- Cooling System: Prevents overheating of the laser source and cutting head.

Applications:

- Metal Cutting: Steel, stainless steel, aluminum, brass, and copper.

- Automotive Industry: Cutting components like chassis, body panels, and exhaust systems.

- Aerospace: Producing lightweight and precise components.

- Electronics: Manufacturing intricate parts for devices and circuits.

- Jewelry: Intricate cutting of metals for custom designs.

- Medical Devices: Fabricating surgical tools and implants.

Advantages:

- High Precision: Suitable for intricate cuts with tight tolerances.

- Speed: Faster than traditional cutting methods, especially for thin materials.

- Versatility: Cuts a wide range of materials and thicknesses.

- Energy Efficiency: Consumes less power compared to other laser cutting technologies like CO₂ lasers.

- Low Maintenance: Fiber lasers have fewer moving parts and longer lifespans.

- Compact Design: Fiber lasers are smaller and more portable than traditional systems.

Assist Gases and Their Roles:

- Oxygen: Enhances cutting speed for thick materials but may cause oxidation on the cut edges.

- Nitrogen: Produces clean, oxidation-free cuts, ideal for stainless steel and aluminum.

- Compressed Air: Cost-effective option for thinner materials.